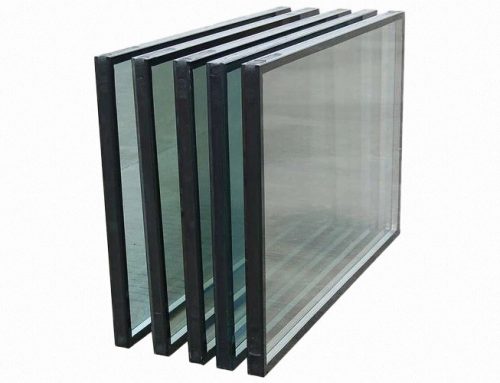

There are many factors that affect building energy efficiency, such as the main wall, house surface, ground, doors and windows, etc. Among these influencing factors, doors and windows have the most unsatisfactory effect in terms of thermal insulation performance, so they are the most important factor affecting building energy efficiency. In the context of modern big data, according to questionnaire survey data, it is found that in the cold season, if the doors and windows of a building are made of single-layer glass, the heat emitted through the doors and windows will account for about 40% of the total heating heat; in the hot season, Due to the solar radiation passing through the single-layer glass doors and windows, the heat radiated into the room consumes about 25% of the total air-conditioning in the room. Therefore, the building requires glass to be able to truly maintain the effect of heat preservation and heat insulation, which is also a key measure to completely improve the indoor environment and improve the energy-saving effect of buildings, and insulated glass can well meet these requirements.

Type of Glass

1. Transparent glass

If the transparent glass is used when making doors and windows, then the sunlight can be easily reflected to the home through the transparent glass. In addition, compared with the emissivity of other types of glass, the emissivity of transparent glass is higher. Even at night, transparent glass will emit energy to the outdoor in the form of radiant heat.

2. Heat-absorbing glass

If the doors and windows use heat-absorbing glass, compared with transparent glass, the heat-absorbing glass can weaken the heat of some light sources by its own coloring, thereby reducing the heat penetration rate and increasing the absorption rate of the doors and windows. At the same time, the heat dissipation of the heat-absorbing glass itself is carried out by the air flow of the outer layer of the glass, which dissipates the heat generated by its own heat absorption, so that outdoor heat rarely enters the room. However, the main disadvantage of the heat-absorbing glass is that it can only weaken the heat emitted by sunlight. If the heat mainly comes from the temperature difference, it will be difficult for the heat-absorbing glass to reduce the heat emitted into the room.

3.Low-E glass

In many energy-saving glass, Low-E glass has a typical representative role, which is mainly due to the bidirectional reflection effect of Low-E glass in dealing with infrared radiation. It can not only effectively reduce the heat generated outdoors to transmit indoors, but also efficiently reflect the heat generated indoors to the outdoors, Therefore, Low-E glass can greatly reduce the heat transmittance. Compared with other types of glass, Low-E glass can reduce the heat by more than 50% on the basis of ordinary glass hindering the heat transmission, and it can also effectively absorb the visible light into the room. Therefore, Low-E glass installed on the doors and windows of the home will not affect the lighting effect of the home, so Low-E glass is one of the better energy-saving glasses.

Choose Different Original Glass According to Different Areas

When we choose the original glass for doors and windows, we need to choose according to the irradiation conditions in different areas. If the place where the door and window glass is installed is in the place with strong sunlight, it is recommended to choose the coated glass with low light and heat transmittance, or the heat absorbing glass with better heat dissipation effect, so as to better control the proportion of indoor light and heat. However, if the area where we are located is relatively cold, we often turn on the heating in the room. Therefore, when we choose the original glass of doors and windows, our main consideration is how to reduce the indoor heat emission. At the same time, we also need to try our best to increase the heat transmitted by sunlight to the room. In this case, we can choose the coated glass with higher transmittance.

The insulated glass made of Low-E glass can effectively prevent the transmission of outdoor heat to the room, and can reduce the ultraviolet radiation. At the same time, this kind of insulated glass has high efficiency of reflecting heat, Therefore, the insulated glass made of Low-E glass can effectively prevent the heat from indoor to outdoor in the cold season and reduce the heat loss of human body. At the same time, the insulated glass can effectively prevent the transmission of outdoor heat to indoor in hot weather season. Therefore, the energy-saving effect of insulated glass made of Low-E glass can be increased by more than 30%.

Type of Spacer Gas

The reason why the coefficient of heat transmission of insulated glass is about 50% lower than that of other single glass is mainly due to the effect of space gas in the insulated glass. To greatly improve the energy saving effect of insulated glass doors and windows, we can fill the hollow cavity with gas, not all the gases can be filled into the hollow cavity. This gas must have certain chemical stability and the coefficient value of heat transmission must be low. Generally, krypton gas and argon are the most common gases in the interval layer. In krypton and argon, people often choose argon, mainly because the charge cost of argon is relatively low, and the following effects can be achieved by filling argon in the interval layer of insulated glass:

(1) It can reduce the loss caused by heat transfer, because compared with air, argon has a lower heat transfer coefficient.

(2) Compared with air, argon is heavier, so if argon is filled in the insulated glass, the argon will not flow easily, thereby reducing the loss caused by convection.

Compared with argon gas phase, the performance of krypton gas is better. If krypton gas of about 8mm is filled in the spacer layer, the energy saving effect is obvious, but the price of krypton gas is more expensive, and enough argon is filled in the spacer layer Gas can also increase the energy-saving effect of insulated glass by about 15%.

Filling the spacer layer of the insulated glass with inert gas can not only improve the energy-saving effect of the glass, but also enhance the comfort of the indoor environment. The main reason is that gas is filled in the spacer layer, which increases the temperature inside the glass, thereby weakening the condensation problem caused by the temperature difference. When the glass surface is relatively warm, people will feel comfortable when approaching.

The Thickness of The Hollow Cavity

Among the factors affecting the energy-saving effect of insulated glass, the thickness of the hollow cavity has a greater impact on the energy-saving effect. If the internal gas convection in the insulated glass hollow cavity is ignored, the heat transfer coefficient of the air is basically constant, and the thickness of the insulated glass hollow cavity is inversely proportional to its heat transfer coefficient, that is, the thicker the hollow cavity is, the lower the heat transfer coefficient of the insulated glass is, so the energy saving effect of the insulated glass is better. But this situation does not always exist. When the thickness of the insulated glass spacer reaches a certain value, the internal convection coefficient of the spacer will increase, so that the energy saving effect of the insulated glass will not be directly proportional to the thickness of the spacer.

The thickness of inert gas in insulated glass hollow cavity is an important reference in judging the energy-saving effect of insulated glass. Nowadays, the insulated glass hollow cavity made in many countries is 12mm, but now the insulated glass with the thickness of 16mm is gradually emerging.

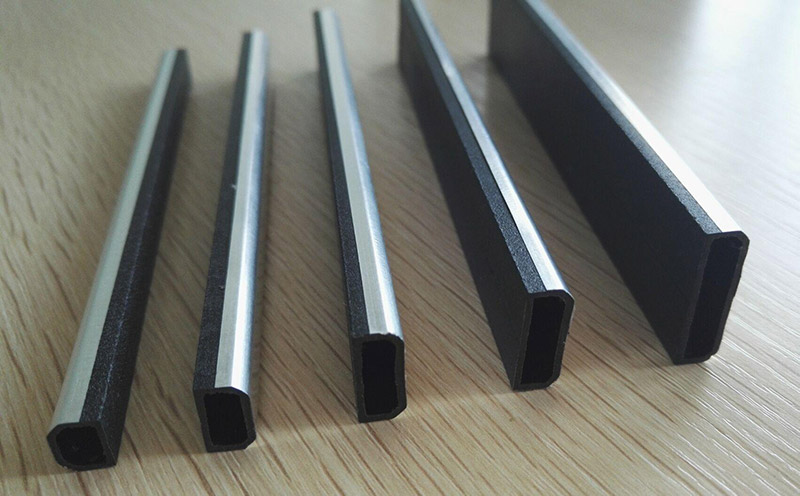

Type of Spacer Bar

In order to improve the energy-saving effect of insulated glass, many professionals are developing spacers with warm edge technology. In the past, spacers in insulated glass were mainly made of metal (tin bars, aluminum bars, etc.). However, because of the better heat transfer effect of metal, the edge of insulated glass spacers is prone to produce water vapor in the cold season, resulting in the damage of insulated glass, the energy saving effect is reduced. The spacer strip with warm edge technology can well deal with the edge thermal conductivity of insulated glass. It is generally designed as composite rubber strip, glass fiber strip, etc., with low thermal conductivity.

If the spacer strip with warm edge technology is used in insulated glass, the following energy-saving effects can be achieved:

(1) The heat loss at the edge of insulated glass can be reduced by the spacer strip with warm edge technology. If the temperature inside the insulated glass interlayer will continue to rise in the colder season, under the continuous radiation of the external sunlight and the opening of the indoor heating, if the Low-E coated insulated glass is used, the temperature inside the insulated glass interlayer will rise by more than 8 ℃, which will lead to a large difference between the inner and outer temperature of the insulated glass, Larger temperature difference will accelerate the heat loss of insulated glass edge.

(2) Greatly reduce the condensation probability around the insulated glass. If the spacer strip with warm edge technology is used, even in the cold season, because of its warm edge characteristics and better thermal resistance, it can better solve the condensation in the glass.

In the past, the construction industry required glass to have better sealing and daylighting properties. With the rapid development of science and technology, the requirements for glass in the construction industry are gradually increasing. The glass used must have better energy-saving effects on the basis of its original performance. With the characteristics of reliable safety and strong pressure resistance, insulated glass can well meet the new demands of modern buildings for glass doors and windows, as well as the new demands of glass in more industries.