Display Cabinet Insulated Glass Door

Quisure Display Cabinet Insulated Glass Door has a variety of properties to choose and customize, from glass color, spacer type, glass thickness, cooling temperature, etc. it is applied to cooler, freezer, wine cabinet, display cabinets, vending machine, etc

Specifications

Product Name

Display Cabinet Insulated Glass DoorInsulation

Double Glazing, Triple GlazingGlass Type

Tempered, Low-EGlass Color

Black, Silver, Red, Blue, Green, Gold, CustomizedGlass Thicknesses

3.2/4mm glass + 12A + 3.2/4mm glass3.2/4mm glass + 12A + 3.2/4mm glass

3.2/4mm glass + 6A + 3.2mm glass + 6A + 3.2/4mm glass

Customized

Spacer Bar

Super spacer strip, Aluminum strip, PVC strip, Thermoplastic warm edge spacer stripTemperature

5~22℃Application

Cooler, Freezer, Wine Cabinet, Display Cabinets, vending machine, etc.Package

EPE foam + Seaworthy wooden case (Plywood Carton)Est. Time(days)

30Service

OEM, ODM, etc.Warranty

2 YearsDescription

Quisure Display Cabinet Insulated Glass Door is using the upgraded float tempered Low-E glass, which is anti-collision, explosion-proof with hardness of automobile windshield. Commonly the glass door is double glazing which filled with Argon, Krypton is optional. Triple glazing is for better UV resistance. Quisure Display Cabinet Insulated Glass Door can meet the temperature requirement from 5℃-22℃, the gasket with strong magnetic can prevent cold air leakage and more power-efficient. Frame can be PVC, aluminum alloy, stainless steel with any color you like to meet your different market need or taste. Recessed, Add-on, Full long or customized handle can also be an aesthetic point.

Features

- Anti-fog, Anti-condensation, Anti-frost

- Anti-collision, Explosion-proof

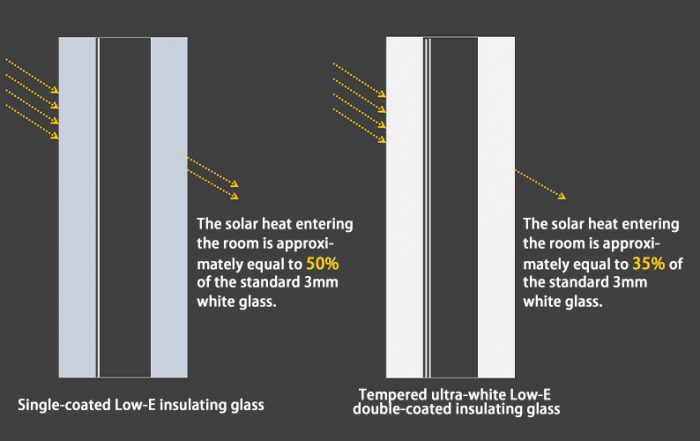

- Tempered Low-E glass inside to improve insulating performance

- Self-closing function

- 90ohold-open feature for easy loading

- High visual light transmittance

- Double Glazing or Triple Glazing

- Heating function is optional

- Bright & Clean Surface

- Flush with the surface and ideal for tight spaces

- Silk Print Logo

- Painting Low E Tempered Glass

Faqs

Insulating glass units, or IGUs, are designed to keep homes warmer in the winter and cooler in the summer.

An insulating glass unit commonly consists of two (sometimes more) panes of glass separated by a spacer material and sealed together at the edge. The insulating airspace is filled with air or a noble gas, such as argon or krypton inside. Each glass pane has two surfaces, so typical double-paned IGUs have four surfaces.

Using argon or krypton in the air space between the two panes of glass provides further insulation, as these gases are denser than air and less likely to let heat conduct through the IGU. Combined with a low-e glass coating, these gases work to improve the window’s overall u-value, which is a measure of the heat transmission through a building part (such as a wall or window). The lower the u-value, the better the insulating glass unit.

When 90% argon gas fill is used in a low-e IGU instead of air, the window’s u-value can be improved by up to 16%. Similarly, krypton improves the u-value in a low-e IGU by up to 27%. However, using a noble gas instead of air in an IGU can add both time and cost to the window’s construction.

Insulating glass (also referred to as “insulated glass”) refers to two or more lites of glass sealed around the edges with an air space between to form a single unit.

Commonly referred to as an “IGU,” insulating glass is the most effective way to reduce air-to-air heat transfer through the glazing. When used in conjunction with low-E and/or reflective glass coatings, IGUs become an effective means to conserve energy and comply with building codes.

The most common architectural insulating glass unit configuration is 1/4″ glass, 1/2″ air space and 1/4″ glass.

Insulated glass panels consist of two panes of tempered glass separated by a spacer. The space between the two panes of glass is filled with air, which provide insulation. These are most often used in residential window applications.

These are custom manufactured dual pane window units, meant to replace existing windows in your home. You can select glass pane thickness and overall sealed window unit thickness. These can be purchased with or without the white grid between the panes.

Regular glass, also known as annealed glass, is commonly used for things such as mirrors and windows. During manufacturing, it is cooled very slowly, as to not create tension or compression. Cooling the glass slowly also allows it to be easily cut, reshaped, drilled, and polished. However, regular glass is very fragile and breaks into large, sharp pieces, which can be dangerous.

Tempered, or toughened, glass has become increasingly popular over recent years due to its use in cars, cookware, and mobile devices. Tempered glass is just annealed glass that has been cut to size, reheated, and cooled rapidly. This process makes it much stronger than other types of glass. Although tempered glass cannot be easily cut or reshaped, it is considered safer than regular glass because it shatters into many, many small pieces with more rounded edges. If you’ve ever shattered your smartphone, you can picture the spider-web qualities of broken tempered glass.

Tempered glass is more scratch resistant than regular glass. It is usually the medium of choice for glass tabletops, patio furniture, glass shelves, and skylights because its shards do not commonly cause serious injury. However, because of the extra steps in the manufacturing process, tempered glass is more expensive than regular annealed glass.

Tempered glass is no less energy efficient than regular glass, especially when you go with a C5 Window from Conservation Construction. That’s because we still use all the same extraordinary coating on the glass that makes it energy efficient. We use Neat Glass, LoE-366 Glass Coatings, and Krypton/Argon Gas mixture to ensure lifelong energy efficiency and insulation for the window. On top of this, you’ll get vinyl frame which are foam filled to ensure better strength against air infiltration.

Tempered glass prevents breaks, cracking and everything else in between. It is multiple times stronger than regular glass which prevents it from turning into jagged shards on the floor when guests exit and enter your home. Not to mention tempered glass is about 3x more expensive than regular window glass so you wouldn’t want it in your entire home or you’d be spending a lot more money.

- Single-pane clear glass has very little insulating value. U and R values are around 1.

- Double-pane clear glass cuts U-Value of a single pane in half and increases R-Value two-fold.

- Double-pane glass with LowE Argon gas has low U-Values between 0.25 and 030 and R-Value of 4. This is a quadruple increase in energy efficiency over a single-pane window.

- Triple-pane glass with LowE and Argon gas is a high-performance glass with U-Values between 0.19 and 0.23 and R-Value around 5. This is a 20-30% improvement in energy efficiency over double-pane glass with LowE Argon, and a whopping 500% over single pane clear glass.

- Triple-pane glass with LowE and Krypton gas is among the best high-performance glazing systems available on the market today. It has U-Values between 0.15 and 0.18 and R-Value of around 7. This is a 40-50% improvement in energy efficiency over double-pane glass with LowE and Argon, and a whopping 700% over a single-pane clear glass.

Tempered glass has a minimum surface compression of 10,000 pounds-per-square-inch (psi) and minimum edge compression of 9,700 psi, according to ASTM C1048. That makes it about four times stronger than annealed glass. Heat-strengthened glass has surface compression of 3,500 to 7,500 psi, about twice as strong as annealed glass, with no edge compression standard.

Ironically, the rapid temperature change that gives tempered glass its compression strength may also cause it to shatter, seemingly without warning. On rare occasions, tiny inclusions, including nickel-sulfide, may be present in glass, which can expand during heat treatment, then stop when the glass is cooled and resume growth when the glass is exposed to high in-service temperatures (such as on the sunny exposure of a building). This “phase change” can cause tempered glass to shatter. Heat-strengthened glass is cooled more slowly; consequently, inclusions do not experience a phase change, which essentially eliminates the possibility of spontaneous glass failure

The glass panes are separated by a “spacer”. A spacer, which may be of the warm edge type, is the piece that separates the two panes of glass in an insulating glass system, and seals the gas space between them. The first spacers were made primarily of steel and aluminum, which manufacturers thought provided more durability, and their lower price means that they remain common.

However, metal spacers conduct heat (unless the metal is thermally improved), undermining the ability of the insulated glass unit (IGU) to reduce heat flow. It may also result in water or ice forming at the bottom of the sealed unit because of the sharp temperature difference between the window and surrounding air. To reduce heat transfer through the spacer and increase overall thermal performance, manufacturers may make the spacer out of a less-conductive material such as structural foam. A spacer made of aluminum that also contains a highly structural thermal barrier reduces condensation on the glass surface and improves insulation, as measured by the overall U-value.

- A spacer that reduces heat flow in glazing configurations may also have characteristics for sound dampening where external noise is an issue.

- Typically, spacers are filled with or contain desiccant to remove moisture trapped in the gas space during manufacturing, thereby lowering the dew point of the gas in that space, and preventing condensation from forming on surface #2 when the outside glass pane temperature falls.

- New technology has emerged to combat the heat loss from traditional spacer bars, including improvements to the structural performance and long-term-durability of improved metal (aluminum with a thermal barrier) and foam spacers.

Cases

Related Technology

How Is The Double-Layer Insulating Glass Made And What Is Its Function?

The method of making the double-layer insulating glass 1. Glass cutting material The original glass is generally colorless float glass

What is The Difference Between Insulating and Vacuum Glass?

In reality, many people confuse insulating glass and vacuum glass. In fact, the two types of glass are very different

Three Factors Affecting the Thermal Performance of Low-E Glass

I.Overview of the electromagnetic spectrum In the spectrum family, in addition to visible light, there are other family members, they