I.Overview of the electromagnetic spectrum

In the spectrum family, in addition to visible light, there are other family members, they are collectively referred to as electromagnetic waves. From a scientific point of view. Electromagnetic waves are a kind of energy. Anything above absolute zero,will release electromagnetic waves. Just as people have been living in the air but their eyes cannot see it, in addition to light waves, people also cannot see electromagnetic waves in everywhere.

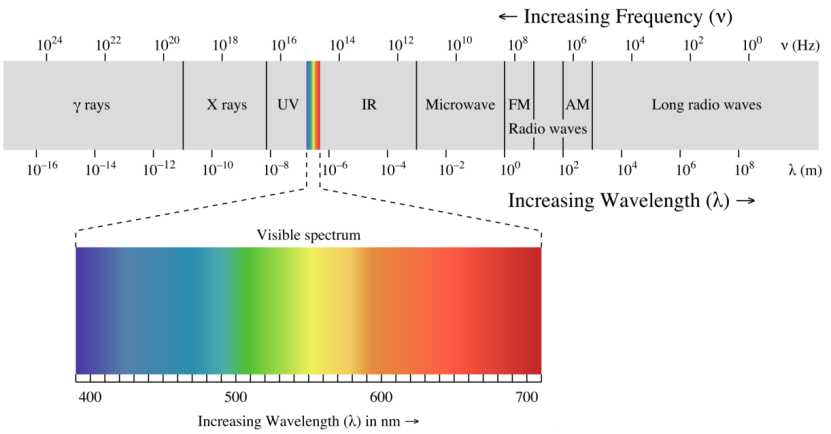

The electromagnetic spectrum can be arranged in the order of wavelength or frequency. If the frequency of each band is arranged from low to high, they are power frequency electromagnetic waves, radio waves, infrared rays, visible light, ultraviolet rays, X-rays and γ- rays. The wavelength of radio is the longest, and cosmic rays have the shortest wavelength.

The Radio waves wavelength is 3000m-0.3mm. Microwaves wavelength is 0.1-100cm, infrared rays wavelength is 0.3mm-0.75μm among them:

Near infrared is 0.76-3μm, mid-infrared is 3-6μm, far-infrared is 6-15μm, ultra-far-infrared is 15-300μm, visible light is 0.7-0.4μm, ultraviolet light is 0.4μm-0.4nm, X-ray is 10-0.1nm. γ-ray 0.1-0.001nm: High-energy rays are less than 0.001 nm, and the fax (television) is 3-6m. The radar wavelength is even shorter, from 3 meters to several millimeters. The electromagnetic wave spectrum distribution diagram is shown in following Figure 1.

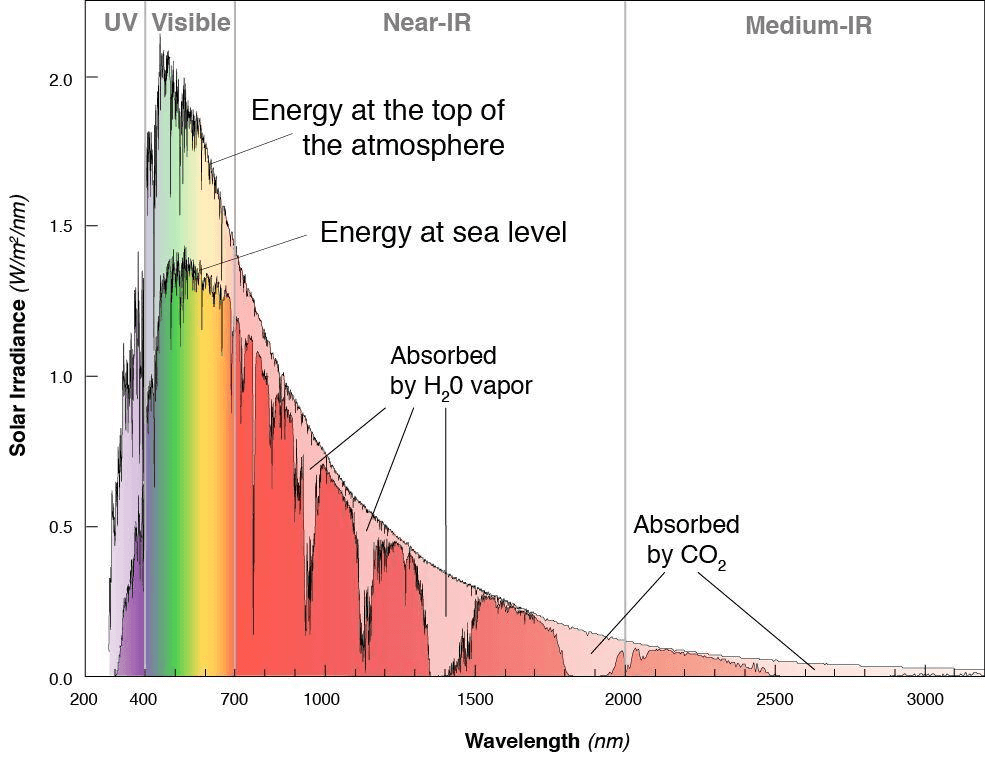

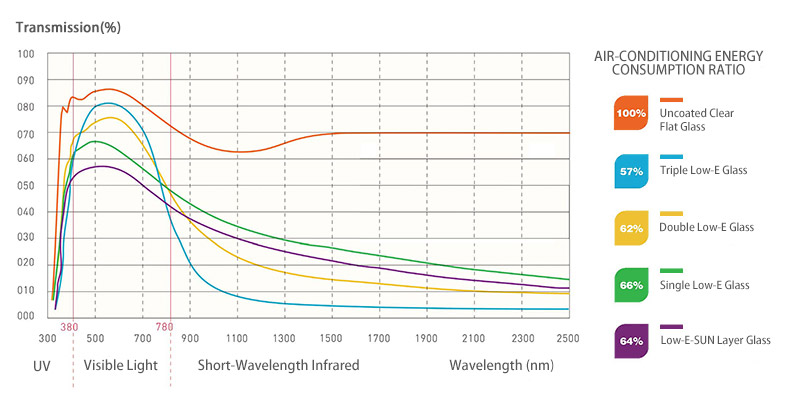

Figure 2 shows the distribution of solar radiation energy. It can be clearly seen from the figure that solar radiation is mainly concentrated in the visible light part (380-780nm), infrared light (>780nm) and ultraviolet (<380nm) part is less. In all solar radiation, the wavelength of 150-4000nm more than 99%, and mainly distributed in the visible and infrared regions, the visible accounts for about 50% and the infrared accounts for about 43%, and the solar radiation energy in the ultraviolet region is very small, accounting for only for 7%.

II.Low-E Glass

1. The Concept of Low-E Glass

Low-E glass——-coated low-emissivity material and metal oxide film on the glass surface to make the glass show different colors. Its main function is to reduce the U value of the glass, and at the same time selectively reduce Sc, and comprehensively improve the energy-saving characteristics of the glass. Low-E glass is also called low-temperature radiation coated glass. The energy saving of coated glass is achieved by changing the heat reflection characteristics of the glass surface. Due to the choice of different coating materials and film structures, two series of products are formed, namely heat reflection Coated glass and low temperature radiation coated glass.

2. Manufacturing Method of Low-E Glass

There are two main manufacturing methods for Low-E glass:

(1) On-line high-temperature pyrolysis deposition method: It is to spray metal liquid or metal powder directly onto the surface of hot glass. As the glass cools, the metal film layer gradually becomes a part of the glass.

(2) Offline vacuum sputtering method: refers to the coating of a multilayer composite film on the surface of the glass. On-line Low-E glass can be used as a single piece or for deep processing such as tempering and hot bending. It can be stored for a long time and is not easily deteriorated. It is especially suitable for application in special-shaped buildings. And harsh environments. Offline Low-E glass has poor stability and cannot be used or stored as a single piece. Usually the float glass is now tempered and then coated with a Low-E film. After coating, the insulating glass must be synthesized immediately. Otherwise, the film layer will be oxidized in long-term contact with air and lose Low-E energy saving performance. In addition, off-line Low-E glass can be coated on glass substrates with a thickness of not more than 20mm, and can be produced in one time according to the required color. On-line Low-E glass is generally only coated on glass substrates with a thickness of 4mm, 5mm, and 6mm, and the color is only gray-blue and clear. The variety is simple and the selectivity is small.

3. Characteristics of Low-E glass

(1) Excellent thermal performance

Relevant studies have shown that the heat transfer on the inner surface of the glass is dominated by radiation, accounting for 58%, which means that the most effective way to reduce the loss of heat energy by changing the performance of the glass is to suppress the radiation on the inner surface. The emissivity of ordinary float glass is as high as 0.84. When coated with a low-emissivity film based on silver, its emissivity can be reduced to below 0.1. Therefore, the use of Low-E glass can greatly reduce the transmission of internal heat energy caused by radiation to the outside, and achieve the ideal energy-saving effect.

(2) Good optical performance

Low-E glass has a high transmittance of visible light in sunlight, up to 80% or more, while the reflectivity is very low, which makes its optical performance greatly improved compared with traditional coated glass. From the inside to the outside, the appearance is more transparent and clear, which guarantees good lighting and avoids the light pollution caused by the light reflection of large-area glass walls and hollow glass in the past, creating a softer and more comfortable light environment.

(3)The transmittance of Low-E glass

It can be clearly seen from the figure that, compared with coated glass, Low-E glass has a high visible transmittance, thus ensuring high day lighting performance, and at the same time has a very low infrared transmittance, which effectively blocks heat radiation.

III.The Heat Transfer Principle and Thermal Performance Evaluation Index of Low-E Glass

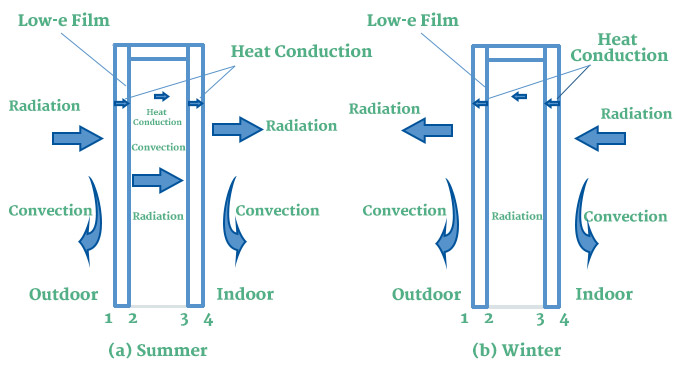

As mentioned earlier, since offline Low-E glass will not be used in a single piece, usually Low-E glass is composed of two or more pieces of glass. Each piece of glass is sealed with silicone to seal the hollow cavity of the stroke, and the hollow cavity is filled dry air or inert gas. According to the principle of energy transfer, the heat transfer principle of Low-E glass is shown in Figure 4. When there is a temperature difference between the two sides of Low-E insulating glass, the heat is transferred from the high temperature side to the low temperature side through the components.

The heat transfer can be divided into two parts, one is the direct heat transfer SHGC from the sun, and the other is the heat transfer caused by the temperature difference between indoor and outdoor. The heat transfer caused by the temperature difference between indoor and outdoor mainly includes: (1) the radiation and convection of the outdoor environment and the outer surface of the component (2) the heat conduction inside each layer of glass plate; (3) the heat conduction and convection of the gas in the hollow cavity; (4) Radiation between the hollow glass plates; (5) Radiation and convection from the inner surface of the component and the indoor environment.

According to the heat transfer principle of Low-E insulating glass, the following parameters are used to evaluate the thermal performance of Low-E insulating glass.

(1) Heat transfer coefficient

The so-called heat transfer coefficient refers to the total heat transfer coefficient when the temperature difference between the two sides of the building is 1℃, the heat transferred through the unit area of the component per unit time is called the total heat transfer coefficient. The standard U value is represented by Uw for the entire glass insulation system, and U2 for Low-E insulating glass. According to its heat transfer principle, U2 can be represented by the following formula:

1/UE=1/h。+1/hi+∑1/(h。+hr)+ ∑(dm+rm) (1)

h=4∑T3/(1/E1+1/F2-1) (2)

In the formula: h0 and hi are the heat transfer coefficients of the outdoor and indoor surfaces of the glass, respectively

Hg—the heat transfer coefficient of the n barrier gas (including convection and conduction);

Hr—the radiation conductivity of the glass surface on both sides of the n barrier

E1, E2—the emissivity of the glass surface on both sides of the n layer of interlayer

dm and rm — are the thickness and thermal resistance of the m layer of glass, respectively.

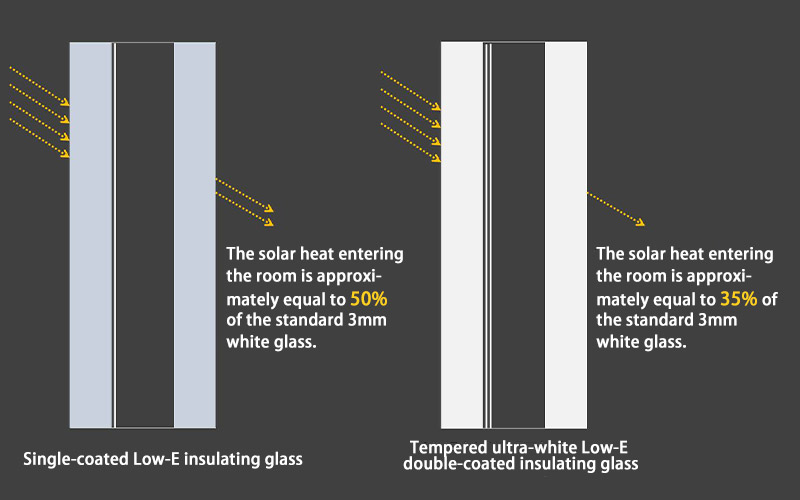

(2) Shading coefficient Sc

The shading coefficient Sc is the ratio of the solar heat gain through the glass to the solar heat gain through a single layer of 3mm colorless glass under the same conditions. Under the assumed summer conditions, the solar heat gain and the solar radiation amount through the 3mm white glass The ratio is 0.87, and this value is called the sunlight gain factor “SHGF”. “SHGC” is called the solar heat gain coefficient, which is the percentage of the solar heat gain through the glass to the solar radiation. So: Sc=SHGC/SHGF(3)

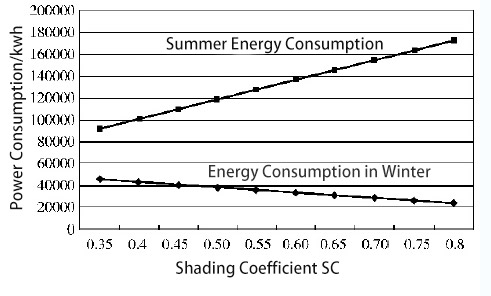

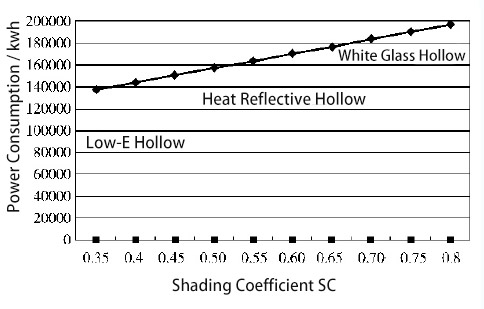

For the hot areas of low latitudes, we can easily understand that buildings want the lowest possible shading coefficient to reduce cooling costs. However, for cold areas at high latitudes, the requirements for shading coefficient are not as high as people think, the better. The following two figures compare the relationship between energy consumption and shading coefficient in winter, summer and throughout the year in cold areas:

It can be seen from Figure 7 and Figure 8 that for public areas in cold areas, although the energy consumption in winter increases slightly with the decrease of the shading coefficient, the energy consumption in summer is greatly reduced with the decrease of the shading coefficient. Therefore, for the total energy consumption, the lower shading coefficient, the lower the energy consumption.

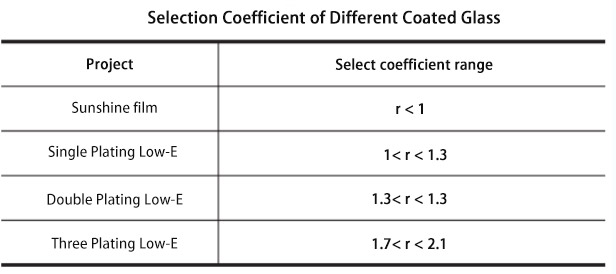

(3). Selection coefficient

The development process of Low-E glass from single silver to double silver or even triple silver, in addition to the pursuit of lower heat transfer coefficient, is more important to solve the contradiction between the high lighting performance of architectural glass and the lowest possible shading coefficient. The selection coefficient r is used to measure this pair of contradictions.

r=Tvis/Sc (4)

In formula (4), Tvis represents the visible light transmittance, and Sc represents the shading coefficient. People always hope that the r value is bigger is better. Table 2 shows the selection coefficient range of various coated glasses.

IV.Conclusion

The thermal performance of Low-E glass is usually measured by the heat transfer coefficient U value, the shading coefficient Sc and the selection coefficient r. These three values directly affect the performance of Low-E glass. The development of coating technology is centered on how to optimize these three indicators.