Commercial vertical display cabinet is a product which not only meets the quality requirements of retail products for refrigeration and preservation, but also has the function of displaying goods. With the development of market demand for commercial vertical display cabinets, the requirements for saving and performance of display cabinets are also increased. Insulated glass doors are mainly used in vertical display cabinets because of their good light transmittance, which can meet the needs of commodity display effect, and their low thermal conductivity, which can maintain the temperature required for commodities for refrigeration in cabinets. The heat insulation performance of insulated glass door directly affects the heat exchange rate inside and outside the cabinet, and ultimately affects the energy consumption of the display cabinet.

Introduction to Insulated Glass

1. Glass type

Two-glass single-cavity insulated glass is commonly used in commercial vertical display cabinet. The common glass is plain toughened glass and coated Low-E glass. The coated Low-E glass is divided into online Low-E glass and offline Low-E glass according to process.

2. Principle of action of LOW-E glass

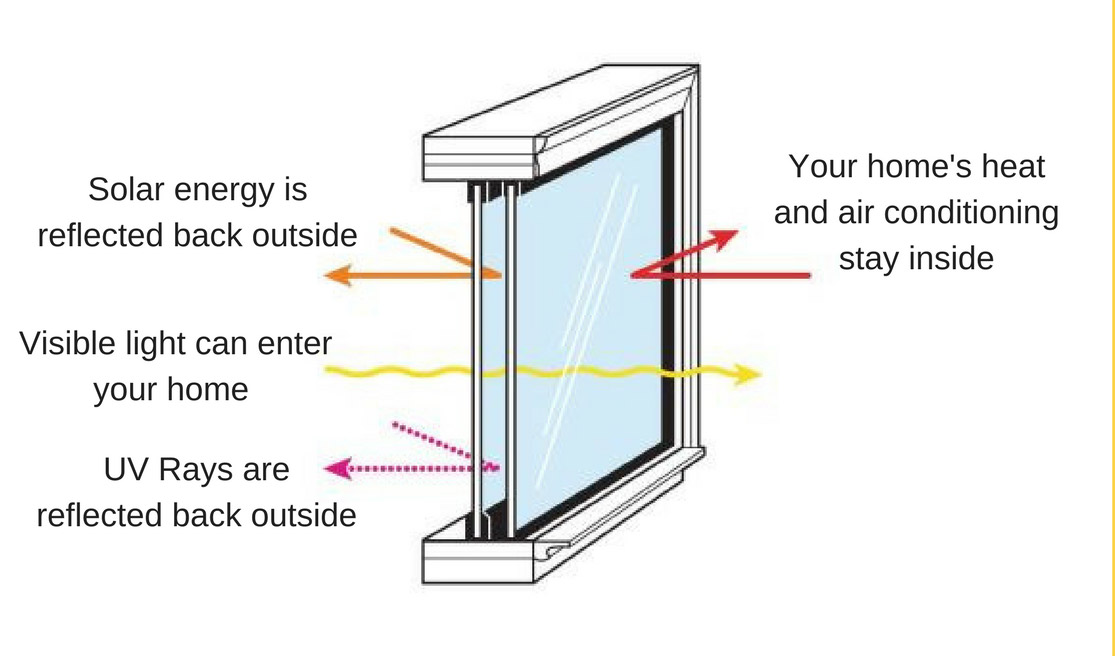

Low-E glass is the abbreviation of Low Emissivity Glass. Its main feature is to add multiple layers of metal or other compounds to form a metal film on the surface of the toughened glass through a coating process. The film has a high transmittance to visible light and has a wavelength of 2.5μm~ The far-infrared radiation of 40μm has a high reflectivity to achieve good thermal insulation performance (U). The lower the U value, the better the thermal insulation effect.

(1) Online Low-E glass.Liquid metal or metal powder is sprayed directly onto the surface of hot glass by on-line pyrolysis deposition. In this way, the on-line Low-E glass is produced and the metal film becomes part of the glass.It is effective to reduce the radiation value relative to float glass, has good thermal insulation and is not easy to scratch, so it is called hard coating.

(2) Offline Low-E glass.The off-line Low-E glass is produced by vacuum magnetron sputtering with single, double or multiple silver functional films on the glass surface.The U value of offline Low-E glass is better than that of online Low-E products.However, the off-line low-E glass silver oxide film is very fragile and easy to oxidize, so it must be made into insulated glass for long-distance transportation.

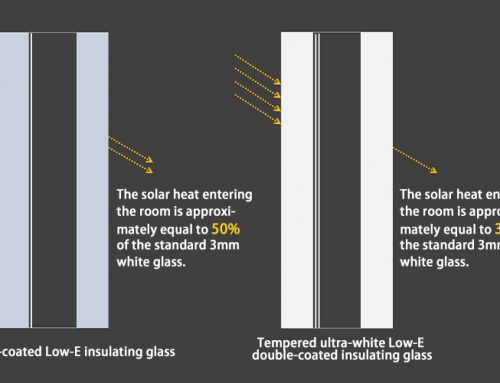

3. Influence of Low-E coating surface position on thermal insulation performance of insulated glass

As shown in Figure 1, the LOW-E glass film layer is installed on the second and third sides of the insulating glass from the outside of the cabinet. The low-emission (Low-E) film has the same reflection performance and radiation performance for long-wave infrared rays on both sides, and the U value has little effect. However, due to the different media on both sides, the film layer is on the second or third side. It has different effects on the shading coefficient of Low-E film insulated glass. The shading coefficient (SC) is the ability of the glass to block or resist sunlight. The smaller the shading coefficient, the better the performance of blocking sunlight heat from radiating indoors. Among them, the shading coefficient of the single-cavity two-glass low-emissivity coating on the second side is smaller than that on the third side.

Design of Insulated Glass for Commercial Vertical Display Cabinet

Insulated glass doors for commercial vertical display cabinets are used in environments where the outside room temperature is higher than the inside temperature. Therefore, when using single-layer Low-E glass, the coating position of Low-E coated glass should be on the second side (inside the hollow cavity) near the outside of the cabinet.

As the glass thickness increases, the insulative U value of insulated glass decreases, i.e. the thermal insulation performance increases. Filling the hollow cavity of insulated glass with inert gas can effectively reduce the U value of insulated glass. Increasing the width of the cavity also reduces the U value. However, an increase in the glass thickness of the hollow glass will increase the weight of the door and eventually increase the weight pouring moment of the door body, so the pouring moment of the door body needs to be at a safe value during the design process. In addition, the U value improved by replacing toughened glass with online Low-E glass is larger than that improved by online Low-E to offline Low-E.The cost and economy of replacing glass types also need to be considered in actual design.