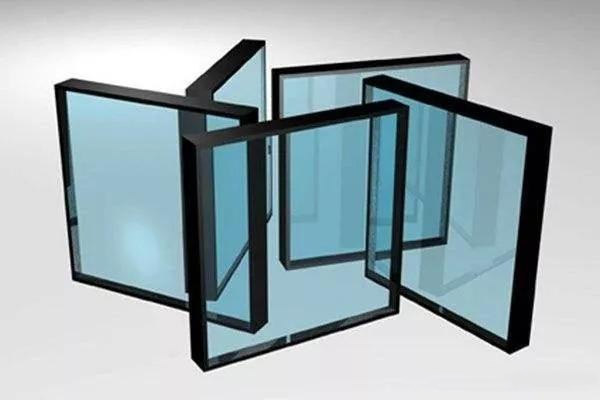

The method of making the double-layer insulating glass

1. Glass cutting material

The original glass is generally colorless float glass or other colored glass, sun-shading glass, tempered glass, laminated glass, the thickness is generally 3 mm ~ 12 mm, the above glass must meet the first grade of GBll614, and regulations for high-quality products can only be used after passing the inspection. Glass cutting can be done by hand or machine, but it should meet the size requirements. During the operation of this process, workers should always pay attention to the glass surface without scratches, uniform internal quality, and no obvious defects such as bubbles and slag inclusions.

2. Glass cleaning and drying

Glass cleaning must use machine cleaning, because manual cleaning cannot guarantee the cleaning quality. The glass must be inspected for scratches before cleaning. In order to ensure the adhesion of the sealant to the glass, it is recommended to use deionized water. In addition, in order to ensure the recycling of water and save water resources, the water can be filtered to ensure long-term use. The cleaned glass must pass the light inspection to check whether there are water droplets, water stains and other stains on the surface of the glass. If there are water droplets, water stains and other stains, the operating speed, heating temperature, air volume, and brush gap of the machine must be checked. Make adjustments until the effect is intact. After washing, the glass should be assembled into insulating glass within 1 hour. In addition, it is necessary to ensure that there is no friction between the glasses. It is recommended to store semi-finished glass in a trolley to separate the glass sheets.

3. Assembly of rubber strip type insulating glass and aluminum strip type insulating glass

Assembly of rubber strip type insulating glass:

(1) Requirements for the environment: The processing temperature of rubber-striped insulating glass is between 10 and 20 degrees in winter and 20 to 30 degrees in summer.

(2) Relative humidity requirements: Since the rubber strip type insulating glass desiccant is in powder form, the desiccant will slow down after mixing with the glue, so the relative humidity of the rubber strip assembly area should be slightly lower.

Aluminum strip type insulating glass assembly:

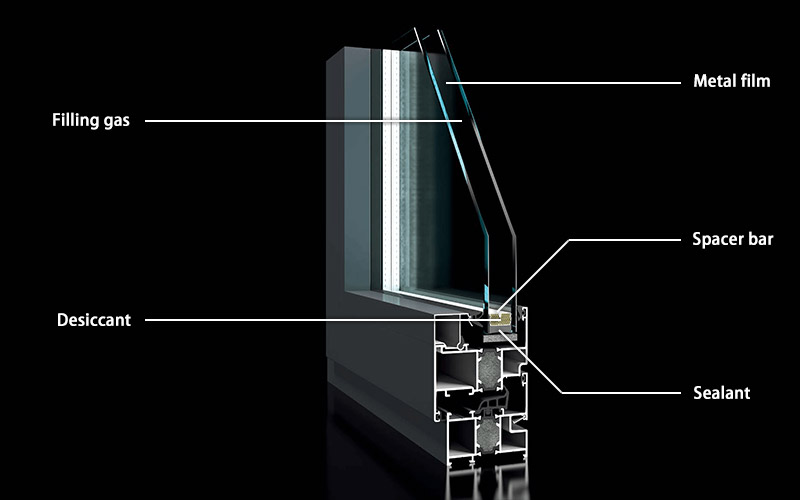

(1) Requirements for the environment: the temperature should be between 10 and 30 degrees.

(2) Relative humidity requirements: This kind of insulating glass has slightly lower requirements for relative humidity, and it is normal. But it should be noted that the desiccant should be a qualified product from a regular manufacturer to ensure effective use. It is recommended that the desiccant be used up within 24 hours after opening, because polysulfide rubber has greater air permeability and poor sealing performance, so double-channel sealing is required. Use butyl rubber as a seal to insulate the gas; use polysulfide rubber as the second seal, mainly for bonding, and secondly for gas barrier. Practice has proved that the life of single-channel sealed insulating glass is only about 5 years, while the life of double-sealed insulating glass can be as long as 20 to 40 years. Therefore, the development of double-sealed insulating glass is a general trend.

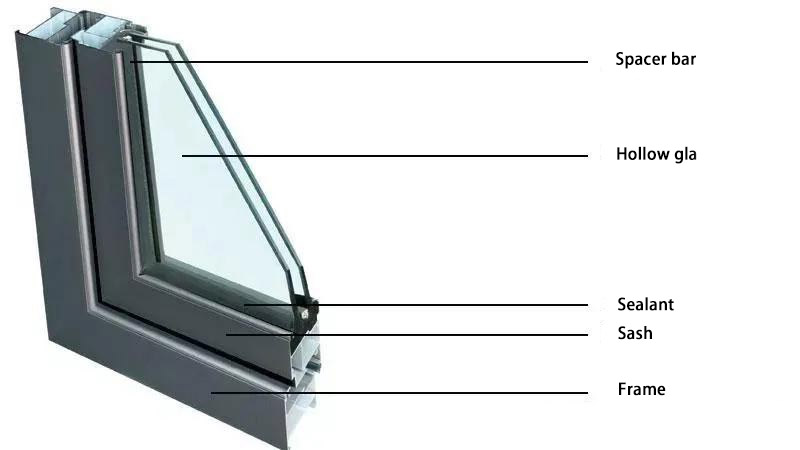

4. Glass pressing

When pressing the rubber strip type insulating glass, pay attention to the alignment of the edges of the combined glass. When pressing, reserve a small opening at the back to allow the dried gas to overflow from the small opening, and then seal it immediately after pressing. So far, the processing of the rubber strip type insulating glass is completed. For aluminum strip type insulating glass, there should be a distance of 5mm~7mm between the outer edge of the aluminum frame and the edge of the glass after the sheets are combined. It is used to apply the second sealant. The silicone glue should be evenly applied along one side to prevent bubbles. , After coating, scrape off the glass surface residue. So far, the processing of aluminum strip type insulating glass is completed.

5. Placement of insulating glass

The correct placement of the insulating glass will also affect the quality of the finished insulating glass. First of all, the design requirements of the stacking rack should take into account the characteristics of insulating glass, and the stacking rack should have a certain inclination. However, the bottom plane and the sides should always be kept at 90 degrees, so as to ensure that the two glass bottom edges of the insulating glass can be placed vertically on the stacking rack. In addition, be careful not to stain the bottom of the glass with oil stains, lime or other solvents, because they will have varying degrees of corrosion on the second sealant of the insulating glass, which will affect the sealing performance of the insulating glass.

The huge advantages of insulating glass

1. Great energy saving effect

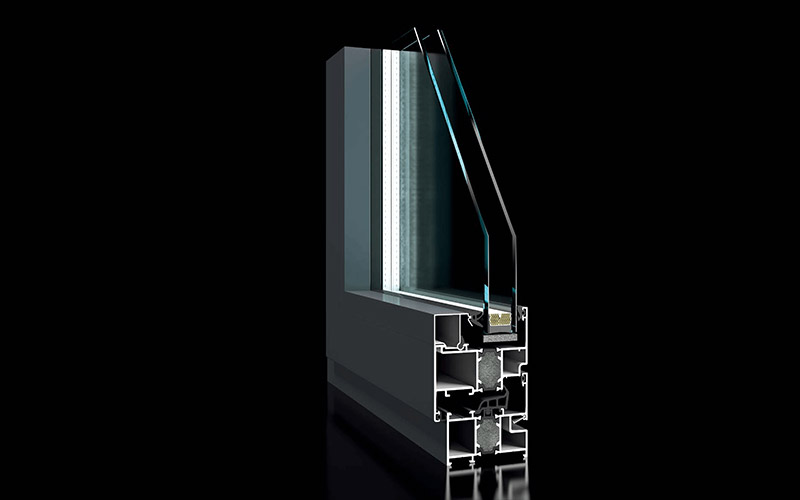

High-performance insulating glass, due to a special metal film, can achieve a shielding factor of 0.22-0.49, which reduces the load of indoor air conditioning (air-conditioning). The heat transfer coefficient is 1.4-2.8W (m2.K), which is better than ordinary insulating glass, and the energy saving effect is obvious.

2. Improve the indoor environment

High-performance insulating glass can intercept considerable energy from the sun into the room, thus preventing discomfort caused by radiant heat and reducing dazzling caused by sunset sunlight.

3. Rich tones and artistry

High-performance insulating glass has a variety of colors, you can choose colors according to your needs to achieve a more ideal artistic effect