Insulated glass is a complex system with a large number of raw materials and complicated production process. In order to produce a piece of qualified insulated glass, it is necessary not only to have high-quality raw and auxiliary materials, but also to carry out self inspection and mutual inspection between each process. In the production process, the environment should be controlled and the operation of employees should comply with the regulations. We analyzed the GB/T 11944-2012 insulated glass standard in China, which puts forward requirements for materials, dimension deviation, appearance quality, dew point, UV radiation resistance, water gas seal durability, initial gas content, gas seal durability and U value.

1. Raw materials

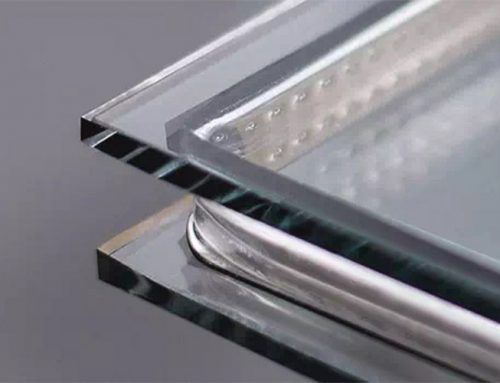

The standard requires that the materials used for insulated glass, such as glass, edge sealing material, spacer material and desiccant, should meet the requirements of corresponding standards.

2. Dimensional deviation

The allowable deviation of the length and width of the insulated glass is shown in Table 1, and the allowable deviation of the thickness is shown in Table 2, the allowable stacking error of the flat insulated glass shall meet the requirements of Table 3.

| Table 1 Allowable deviation of length(width), unit: mm | |

| Length (width)/L | Allowable deviation |

| L<1000 | ±2 |

| l000≤L<2000 | +2、-3 |

| L≥2000 | ±3 |

| Table 2 allowable deviation of thickness, unit: mm | |

| Nominal thickness/D | Allowable deviation |

| D<17 | ±1 |

| 17≤D<22 | ±1.5 |

| D≥22 | ±2 |

Note: the nominal thickness of insulated glass is the sum of the nominal thickness of the original glass sheet and the thickness of the hollow cavity.

| Table 3 allowable stacking error, unit: mm | |

| Length (width) / L | Allowable stacking error |

| L<1000 | 2 |

| l000≤L<2000 | 3 |

| L≥2000 | 4 |

Note: the stacking difference of curved surface and insulated glass with special requirements shall be determined by both parties.

The sealant width of insulated glass outside should not be less than 5mm; The width of the adhesive layer of the composite sealant strip is 8 mm ± 2 mm; The width of inner butyl rubber layer shall not be less than 3mm.

3. Appearance quality of insulated glass

The appearance quality of insulated glass shall meet the following requirements:

(1) Edge sealing: the inner sealant should be uniform and continuous, and the outer sealant should be uniform and neat, fully bonded with the glass, and not beyond the edge of the glass.

(2) Glass: for scratches with width≤0.2mm and length≤30mm, 4pieces/m², 0.2 mm<width≤1mm, length≤50mm, 1 scratch is allowed/m²; Other defects shall meet the requirements of corresponding glass standards.

(3) Spacer material: no distortion, smooth and clean surface; no stains, spots and flaky oxidation on the surface.

(4) Hollow cavity: no foreign matter.

(5) Inner surface of glass: no stain and sealant flowing that hinder perspective.

4. Dew point

The dew point of insulated glass should be less than -40℃.

5. Durability of water air seal

The water permeability index (I value) is used to quantitatively measure the durability of water gas seal. It is required that the water permeability index I≤0.25 and the average value I(AV)≤0.20.

6. Gas content of inflatable insulated glass

The initial gas content of inflatable insulated glass should be greater than or equal to 85%(V/V). The gas content of inflatable insulated glass after gas sealing durability test is greater than or equal to 80%(V/V).

Based on the requirements of the standard, the unqualified products can be avoided in advance in the production of insulated glass, and the yield and quality of insulated glass can be improved.