Upright Display Freezer/Cooler Insulated Glass Door

Quisure Upright Display Freezer/Cooler Insulated Glass Door has a variety of properties to choose and customize, from glass color, spacer type, glass thickness, cooling temperature, etc. it is applied to cooler, freezer, wine cabinet, display cabinets, vending machine, etc

Specifications

Product Name

Upright Display Freezer/Cooler Insulated Glass DoorInsulation

Double Glazing, Triple GlazingGlass Type

Tempered, Low-EGlass Color

Black, Silver, Red, Blue, Green, Gold, CustomizedGlass Thicknesses

3.2/4mm glass + 12A + 3.2/4mm glass3.2/4mm glass + 12A + 3.2/4mm glass

3.2/4mm glass + 6A + 3.2mm glass + 6A + 3.2/4mm glass

Customized

Spacer Bar

Super spacer strip, Aluminum strip, PVC strip, Thermoplastic warm edge spacer stripTemperature

-30℃-10 ℃; 0℃-10 ℃;Application

Cooler, Freezer, Wine Cabinet, Display Cabinets, vending machine, etc.Quality Standards

GB/T11944, Chinese standard. / EN 1279, European Standard. / ASTM E 2190, American standard.Package

EPE foam + Seaworthy wooden case (Plywood Carton)Est. Time(days)

30Service

OEM, ODM, etc.Warranty

2 YearsDescription

Quisure Upright Display Freezer/Cooler Insulated Glass Door is using the upgraded float tempered Low-E glass, which is anti-collision, explosion-proof with hardness of automobile windshield. Commonly the glass door is double glazing which filled with Argon, Krypton is optional. Triple glazing is for freezer use, heating function is optional. Quisure Upright Display Freezer/Cooler Insulated Glass Door can meet the temperature requirement from -30℃-10℃, the gasket with strong magnetic can prevent cold air leakage and more power-efficient. Frame can be PVC, aluminum alloy, stainless steel with any color you like to meet your different market need or taste. Built-in, Add-on, Full long or customized handle can also be an aesthetic point.

Features

- Anti-fog, Anti-condensation, Anti-frost

- Anti-collision, Explosion-proof

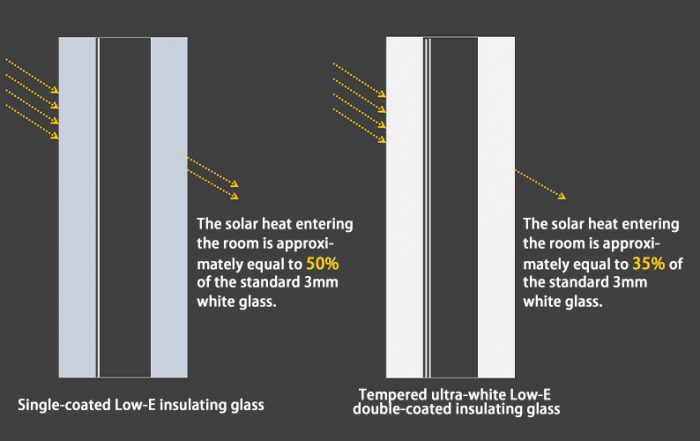

- Tempered Low-E glass inside to improve insulating performance

- Self-closing function

- 90o hold-open feature for easy loading

- High visual light transmittance

- Silk Print Panel / Painting Panel

- Smooth Edge with Edging Process

- Up and down self-closing hinge

- Gasket with strong magnetic

- preventing cold air leakage, and more power-efficient

Faqs

- 1) Annealed Glass. Annealed glass is a basic product formed from the annealing stage of the float process.

- 2) Heat Strengthened Glass. Heat Strengthened Glass is semi tempered or semi toughened glass.

- 3) Tempered or Toughened Glass.

- 4) Laminated Glass.

Tempered glass screen guards are much sturdier and robust in nature than the former. They provide you clarity as much as your smartphone would without any screen protector over its screen. The cleaning becomes much easier on the tempered glass surface as it very smooth.

PROS

- They may be a costlier alternative than the plastic ones, but it safeguards your device better. Tempered glass screen guards are much sturdier and robust in nature than the former.

- Tempered glass is made up of oil and scratch resistant gorilla glass.

- It enhances your usability experience as your fingers glide more smoothly on these screen guards.

- They prevent excessive fingerprints and oil smudges.

- You might not even notice they are on the top of your mobile screen. It doesn’t make your phone look hideous by not compromising with the look of your smartphone. They provide you clarity as much as your smartphone would without any screen protector over its screen.

- The cleaning becomes much easier on the tempered glass surface as it very smooth.

- In case if your tempered glass breaks, it breaks into small, blunt chunks and that doesn’t compromise with the safety it was providing to your phone screen.

- Tempered glass screen protectors are sleek, giving you the maximum image clarity and has the ultimate touchscreen sensitivity.

CONS

- You need to be very cautious while using the glass tempered screen guards, like the moment you crack it, they are done.

- Since it is a glass, chances are you might cut yourself after a bad chip. You shouldn’t reuse a cracked tempered glass screen protector, unlike the plastic ones.

- Tempered glass screen guards don’t offer as much impact protection as promised by a plastic screen guard. The hammer experiments we mentioned above are not meant to be run on these tempered glass screens.

Tempered glass is a heat treated glass. The glass is heated first, followed by the surface being cooled rapidly. This process results in leaving the center of the glass relatively hot, when compared to the center. When the center of the glass does cool, the surface and edges are compressed.

This process is what causes tempered glass to break down into relatively small and harmless pieces, in order to prevent potential injuries. When glass breaks, it can create large shards that pose a threat to anyone that may come in contact with it. “Dicing,” as the process is called when tempered glass shatters, helps reduce the likelihood of serious injury, as a direct result of contact with the window.

Impact-resistant glass is created by use of a safety glaze for laminated glass. This type of glass is created by bonding together two or more panes of glass with a thin clear film between the panes. The thickness of this film can range, as can the UV tint or color. This film also helps to hold the glass in place, making it resistant to impact.

Although laminated glass is stronger than tempered glass, tempered glass is more often used in household windows and doors. Tempered glass offers strength and breakage-resistance but laminated glass provides UV-resistance, extra security, and soundproofing

Tempered glass, also known as toughened glass, is stronger than ordinary glass but can shatter. Similar to laminated glass, when the tempered glass suffers an impact it can break into a web-like interlocking pattern and remain within its frame. This is not always the case as the broken pieces only hold onto adjoining pieces and can fall out of their frame.

Laminated glass is made of two pieces of regular or tempered glass sandwiched around a layer of clear plastic film (PVB). The set of glass is treated through a process intended to expel air pockets and then it is heated for an initial round of melting. After this, the glass is heated under pressure to create a finished bound product. Laminated glass can be made stronger by adding layers making the end product thicker.

Insulated glass is similar to laminated glass in that it is also made of several layers of glass that are bonded together. Unlike laminated glass though, insulated glass is manufactured with spacers around the perimeter of the glass sheets while most of the space between the sheets is hollow. These hollow layers act as insulation, helping to minimize heat or cold transfer through the window or door and helping to improve energy efficiency in your home or business by allowing less of your air conditioned or heated air to leach out through the window.

Laminated glass is probably best known as being the “safety glass” that has been standard in automobile windshields for a number of years. There are real safety benefits to using laminated glass over other types of glass. Laminated glass can still be chipped or cracked, but its design allows it to hold together when it is damaged rather than having shards of glass breaking away and falling, potentially causing injury. Regular glass is extremely dangerous when it breaks because of these razor-sharp shards. Not only does laminated glass offer improved safety, but it is also frequently required in commercial buildings for safety reasons.

Laminated glass is actually two separate sheets of glass with a clear, plastic layer fused between the glass sheets. The plastic layer is invisible, but is what holds the glass pieces together if the glass is ever damaged.

Laminated glass and insulated glass can both lower energy costs and reduce UV rays passing through to the interior of a building, and both types of glass can also be tinted and made in custom sizes to fit nearly any window or door, but each of the two types have their own unique features to consider when selecting the right glass for your home or business.

The glass panes are separated by a “spacer”. A spacer, which may be of the warm edge type, is the piece that separates the two panes of glass in an insulating glass system, and seals the gas space between them. The first spacers were made primarily of steel and aluminum, which manufacturers thought provided more durability, and their lower price means that they remain common.

However, metal spacers conduct heat (unless the metal is thermally improved), undermining the ability of the insulated glass unit (IGU) to reduce heat flow. It may also result in water or ice forming at the bottom of the sealed unit because of the sharp temperature difference between the window and surrounding air. To reduce heat transfer through the spacer and increase overall thermal performance, manufacturers may make the spacer out of a less-conductive material such as structural foam. A spacer made of aluminum that also contains a highly structural thermal barrier reduces condensation on the glass surface and improves insulation, as measured by the overall U-value.

- A spacer that reduces heat flow in glazing configurations may also have characteristics for sound dampening where external noise is an issue.

- Typically, spacers are filled with or contain desiccant to remove moisture trapped in the gas space during manufacturing, thereby lowering the dew point of the gas in that space, and preventing condensation from forming on surface #2 when the outside glass pane temperature falls.

- New technology has emerged to combat the heat loss from traditional spacer bars, including improvements to the structural performance and long-term-durability of improved metal (aluminum with a thermal barrier) and foam spacers.

Tempered glass has a minimum surface compression of 10,000 pounds-per-square-inch (psi) and minimum edge compression of 9,700 psi, according to ASTM C1048. That makes it about four times stronger than annealed glass. Heat-strengthened glass has surface compression of 3,500 to 7,500 psi, about twice as strong as annealed glass, with no edge compression standard.

Ironically, the rapid temperature change that gives tempered glass its compression strength may also cause it to shatter, seemingly without warning. On rare occasions, tiny inclusions, including nickel-sulfide, may be present in glass, which can expand during heat treatment, then stop when the glass is cooled and resume growth when the glass is exposed to high in-service temperatures (such as on the sunny exposure of a building). This “phase change” can cause tempered glass to shatter. Heat-strengthened glass is cooled more slowly; consequently, inclusions do not experience a phase change, which essentially eliminates the possibility of spontaneous glass failure

- Single-pane clear glass has very little insulating value. U and R values are around 1.

- Double-pane clear glass cuts U-Value of a single pane in half and increases R-Value two-fold.

- Double-pane glass with LowE Argon gas has low U-Values between 0.25 and 030 and R-Value of 4. This is a quadruple increase in energy efficiency over a single-pane window.

- Triple-pane glass with LowE and Argon gas is a high-performance glass with U-Values between 0.19 and 0.23 and R-Value around 5. This is a 20-30% improvement in energy efficiency over double-pane glass with LowE Argon, and a whopping 500% over single pane clear glass.

- Triple-pane glass with LowE and Krypton gas is among the best high-performance glazing systems available on the market today. It has U-Values between 0.15 and 0.18 and R-Value of around 7. This is a 40-50% improvement in energy efficiency over double-pane glass with LowE and Argon, and a whopping 700% over a single-pane clear glass.

Cases

Related Technology

How Is The Double-Layer Insulating Glass Made And What Is Its Function?

The method of making the double-layer insulating glass 1. Glass cutting material The original glass is generally colorless float glass

What is The Difference Between Insulating and Vacuum Glass?

In reality, many people confuse insulating glass and vacuum glass. In fact, the two types of glass are very different

Three Factors Affecting the Thermal Performance of Low-E Glass

I.Overview of the electromagnetic spectrum In the spectrum family, in addition to visible light, there are other family members, they